Every component of SOLCOR’s musical instrument cables has the strictest quality standards and is made with the raw materials that provide the best response for transmitting audio signals.

Every component of SOLCOR’s musical instrument cables has the strictest quality standards and is made with the raw materials that provide the best response for transmitting audio signals.

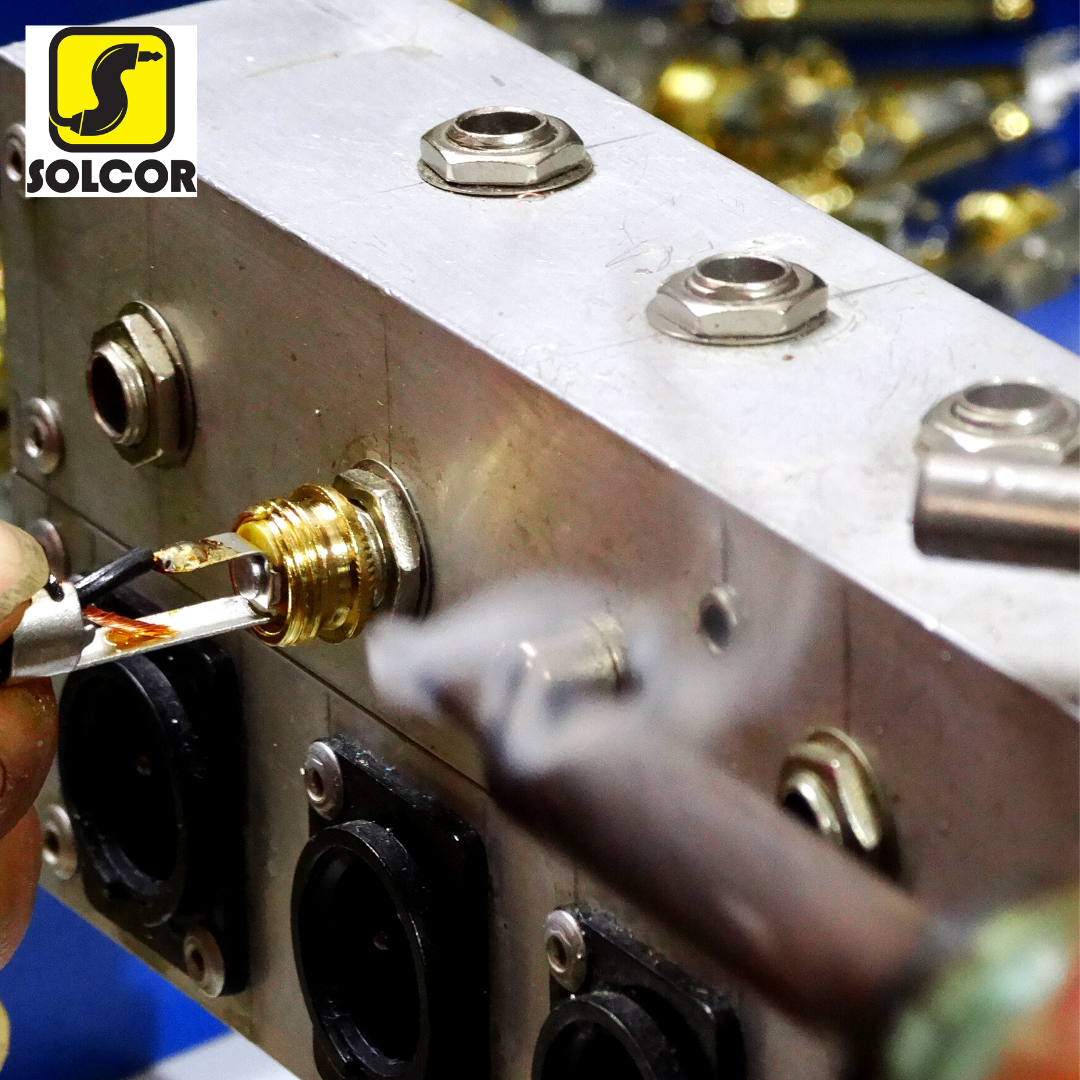

This is the case with our resin-based welding, and here we explain a little more about this component: We are talking about a metal alloy, meaning that two or more metals are combined to create a single body. Welding has been used for a long time to join different metal pieces by heating it to achieve a melting point that creates a liquid bond. When this bond cools, we can return the parts to their original hardness.

There are different types of welding: with gold, zinc, nickel, tin, lead and tin, silver, and resin-based. The latter has more versatility of use and is the most recommended for precisely manufacturing small parts in the electronics industry, in the production of electrical cables, and when working with metals such as tin and copper, which are also elements that are part of our cables.

The SOLCOR resin-based welding is designed to offer high activation flux, which provides excellent welding that improves thermal transfer and wetting.